Last updated September 2023

August 2023

Wiring

With the trackwork all laid and ballasted (with the exception of the plain track to/from the fiddle yard) we have turned our attention to the wiring. There are seven turnouts on the layout, but six of these are paired to form three crossovers. There are no signals on the layout, and no interlocking, so the three crossovers and one turnout are operated by four single-

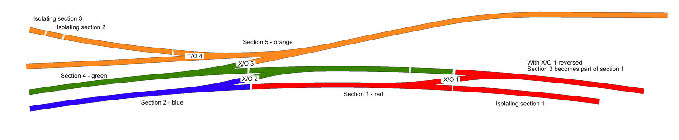

With the trackwork all laid and ballasted (with the exception of the plain track to/from the fiddle yard) we have turned our attention to the wiring. There are seven turnouts on the layout, but six of these are paired to form three crossovers. There are no signals on the layout, and no interlocking, so the three crossovers and one turnout are operated by four single-The layout is wired using the DC ‘cab control’ approach, rather than DCC. (I have looked at DCC for Plumpton Green and rejected it on the grounds of the cost and time effort required to convert 36 engines). Ouse Wharf is designed to be operated by one or two people, and hence needs only two controllers at most. However to give maximum flexibility of operation, and to have potentially three engines ‘in steam’ at any one time, the layout is divided into five sections. The diagram (above) shows the five sections.

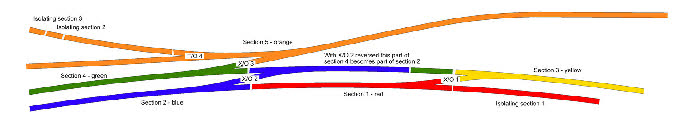

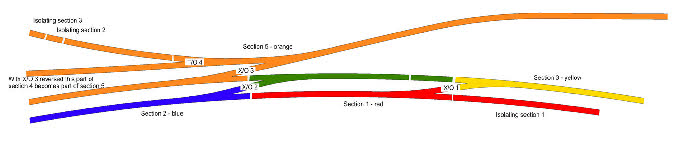

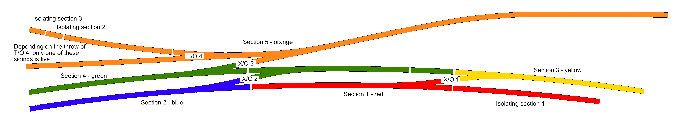

To complicate things further (but to make operation more flexible) sections are switched, depending on the throw of the crossovers. The first diagram below shows the section configuration when crossover 1 is thrown. The second diagram shows the sections when crossover 2 is thrown, and the third diagram when crossover 3 is thrown. Any or all of the crossovers can be thrown simultaneously.

This may seem unnecessarily complex, but it means for example, an incoming train can be shunted into the arrivals road, whilst maintaining all options for shunting quay-

In addition to the above, there are three isolating sections, two to enable locos to be isolated on the engine shed road, and a third at the right hand end of the quay-

Point operation

Point operationThe C&L turnout operating units (TOU’s) are simple enough to assemble, but when coupled with Tortoise motors a problem arises. There is nothing on the TOU to limit movement, and the Tortoise relies on a spring steel wire to drive any mechanism. Adjusting the Tortoise to give the exact amount of movement in both directions is next to impossible, which gives rise to the potential for the Tortoise to ‘overdrive’ the TOU and bend the operating wires. To overcome this, I have added stops to the TOU sliders. These can be finely adjusted to give the required amount of throw in either direction. The spring steel wire on the Tortoise provides the flexibility in the whole mechanism, whilst ensuring that the switch blades throw positively. The photo (left) shows one the the TOU/Tortoise mechanisms as installed. I have used the switches on the Tortoise motors to provide the switching of V’s, and to switch sections as described above.

September 2023

Wiring continues....

Before any testing can be done the control panel is required. This is a fairly simple affair (compared to Plumpton Green), consisting of five sets of radio buttons for the section switches (off or one of two controllers); four T/O C/O switches; three isolating switches; and four other switches for some, as yet undefined, future function.

The photo (left) shows the top of the panel, and (right) in position on the layout.

The photo (left) shows the top of the panel, and (right) in position on the layout.October 2023

With the track laid and wiring complete, and the control panel finished we are able to start testing with an engine. Everything works as it should apart from one connection which was quickly traced and fixed. On a first test with a loco, we have a handful of places where derailment occurs, due to misalignment of rails, either horizontally or vertically -

With the track laid and wiring complete, and the control panel finished we are able to start testing with an engine. Everything works as it should apart from one connection which was quickly traced and fixed. On a first test with a loco, we have a handful of places where derailment occurs, due to misalignment of rails, either horizontally or vertically -We can now start on the scenery, commencing with the river. We will be using 3mm acrylic sheet on top of the painted baseboard, to give the appearance of depth. Once this is in place we can build the wharf wall and start on the tramwayed sections of rail. The water surface will be finished at a much later stage with Woodland Scenics water materials to add surface ripples.