Added March 2020

E3 no 165 ex ‘Blatchington’

E4 no 566 ex ‘Durrington’

E4 no 468 ‘Midhurst’

E4X no 478 ex ‘Newick’

E5 no 584 ‘Lordington’

E6 no 410 ‘Chilgrove’

Following William Stroudley’s experiments with modifications to his 0-

Following William Stroudley’s experiments with modifications to his 0-6-0 tanks in the form of his E1R ‘West Brighton’, his successor Robert Billinton developed a series of 0-6-2 tanks, starting with the goods E3’s. He followed this with the E4 mixed traffic (5ft wheels), E5 passenger tanks (5ft 6” wheels), and finally E6 heavy goods (4ft 6” wheels). Many of the E4, E5 and E6 classes were reboilered with I1 or I2 boilers. Those with the larger I2 boiler had the suffix ‘X’ added as in ‘E4X’.

‘Newick’ no 478 was one of just four E4’s reboilered with the I2 boiler, shown here in its later years.

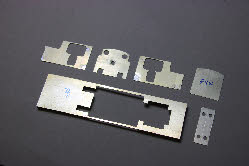

I started cutting out a few parts for an E4X sometime in the 1990’s, but stopped after I acquired a pre-

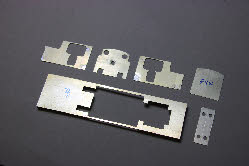

I started cutting out a few parts for an E4X sometime in the 1990’s, but stopped after I acquired a pre-owned white metal body, of a Stenning E4 which required a repaint and a new chassis. My E4X chassis parts got used for this project, and so the other components were left to languish in the to-do box. Towards the end of 2019 , whilst looking for something else, I stumbled across the components (photo left) and decided to finish the engine.

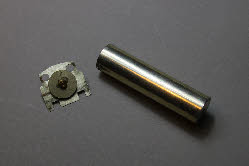

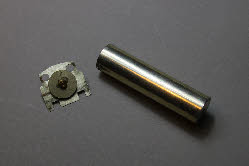

Work progressed fairly rapidly with the completion of the boiler, and assembly of the cab front and saddle. The two photos show the rolled boiler, made from 5th nickel silver, and then the assembly being checked for level.

Work progressed fairly rapidly with the completion of the boiler, and assembly of the cab front and saddle. The two photos show the rolled boiler, made from 5th nickel silver, and then the assembly being checked for level.

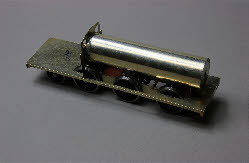

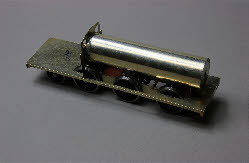

The chassis was made using techniques described elsewhere, and checked for clearance against the running plate.

The chassis was made using techniques described elsewhere, and checked for clearance against the running plate.

With the chassis clearances checked, the cab/boiler assembly was soldered onto the running plate, and the boiler cutaway behind the side tanks, to accommodate the motor, and to enable further checks on clearances.

With the chassis clearances checked, the cab/boiler assembly was soldered onto the running plate, and the boiler cutaway behind the side tanks, to accommodate the motor, and to enable further checks on clearances.

The chassis was then completed and tested, and checked against the body, before the rest of the sheeting (cab sides and rear, bunker rear, and side tanks) were added. All the remaining details and fittings were made and added (always the slowest part), as shown (left), cleaned and ready for painting.

The chassis was then completed and tested, and checked against the body, before the rest of the sheeting (cab sides and rear, bunker rear, and side tanks) were added. All the remaining details and fittings were made and added (always the slowest part), as shown (left), cleaned and ready for painting.

For all of my previous engines, I have used my tried and tested method of making transfers for the lining, but for the E4X I had several unsuccessful attempts at making the cab-side transfers. I eventually gave up and tried lining directly onto the engine, with at least a moderate degree of success. The two photos below show the engine on Plumpton Green, finished with coal and crew, varnished with a satin finish, and lightly weathered.

The E4X’s are not as handsomely proportioned as the original E4, but with the larger boiler they give an unmistakable air of power.

The E4X’s are not as handsomely proportioned as the original E4, but with the larger boiler they give an unmistakable air of power.

E3 no 165 ex ‘Blatchington’

E4 no 566 ex ‘Durrington’

E4 no 468 ‘Midhurst’

E4X no 478 ex ‘Newick’

E5 no 584 ‘Lordington’

E6 no 410 ‘Chilgrove’

Following William Stroudley’s experiments with modifications to his 0-

Following William Stroudley’s experiments with modifications to his 0-‘Newick’ no 478 was one of just four E4’s reboilered with the I2 boiler, shown here in its later years.

I started cutting out a few parts for an E4X sometime in the 1990’s, but stopped after I acquired a pre-

I started cutting out a few parts for an E4X sometime in the 1990’s, but stopped after I acquired a pre-

Work progressed fairly rapidly with the completion of the boiler, and assembly of the cab front and saddle. The two photos show the rolled boiler, made from 5th nickel silver, and then the assembly being checked for level.

Work progressed fairly rapidly with the completion of the boiler, and assembly of the cab front and saddle. The two photos show the rolled boiler, made from 5th nickel silver, and then the assembly being checked for level.

The chassis was made using techniques described elsewhere, and checked for clearance against the running plate.

The chassis was made using techniques described elsewhere, and checked for clearance against the running plate.

With the chassis clearances checked, the cab/boiler assembly was soldered onto the running plate, and the boiler cutaway behind the side tanks, to accommodate the motor, and to enable further checks on clearances.

With the chassis clearances checked, the cab/boiler assembly was soldered onto the running plate, and the boiler cutaway behind the side tanks, to accommodate the motor, and to enable further checks on clearances. The chassis was then completed and tested, and checked against the body, before the rest of the sheeting (cab sides and rear, bunker rear, and side tanks) were added. All the remaining details and fittings were made and added (always the slowest part), as shown (left), cleaned and ready for painting.

The chassis was then completed and tested, and checked against the body, before the rest of the sheeting (cab sides and rear, bunker rear, and side tanks) were added. All the remaining details and fittings were made and added (always the slowest part), as shown (left), cleaned and ready for painting.For all of my previous engines, I have used my tried and tested method of making transfers for the lining, but for the E4X I had several unsuccessful attempts at making the cab-

The E4X’s are not as handsomely proportioned as the original E4, but with the larger boiler they give an unmistakable air of power.

The E4X’s are not as handsomely proportioned as the original E4, but with the larger boiler they give an unmistakable air of power.