Last updated May 2023

Ground signals for Brighton Road

From the modest amount of research I’ve done (mostly trawling through the Signalling Record Society books on LBSCR signalling) it appears the Brighton didn’t have a consistent approach to the use of ground signals. Some locations appear to have a minimalist approach, whilst in other places it seems that virtually every move is signalled. I opted for the latter for Brighton Road, and had ground signals either side of cross-overs, and for entry and exit to both yards. (The exit from the goods yard was controlled by a shunt ahead arm, allowing trains to leave from the yard, up to the starter).

I’m not aware of any commercially available rotating actuators (apart from what was then the new and innovative approach of using radio control aircraft actuators) so I made my own, using ‘Clearbox’ motors as the basis. These are useful motors, running on 3-

I’m not aware of any commercially available rotating actuators (apart from what was then the new and innovative approach of using radio control aircraft actuators) so I made my own, using ‘Clearbox’ motors as the basis. These are useful motors, running on 3-6V, and with cleverly designed gearboxes which can be arranged to give a very wide range of gear ratios. However, these motors don’t have a stop mechanism to allow them to turn through 90deg, and stop automatically.

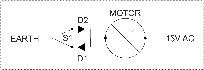

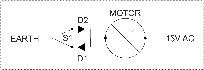

I had a 15V AC supply on the layout, and I used this for motors which need to be run in both directions (turnouts, signals, gates). The basic principle of the electrics is shown in the diagram. Diodes were used to give half-

I had a 15V AC supply on the layout, and I used this for motors which need to be run in both directions (turnouts, signals, gates). The basic principle of the electrics is shown in the diagram. Diodes were used to give half-wave rectification - positive when the switch S1 is thrown in one direction (via diode D1), and negative when thrown in the opposite direction (via diode D2). The motor would therefore run either forwards or backwards, depending on the position of switch S1.

However, this didn’t provide an automatic stop when the signal rotated through 90deg. It worked ok for a gate for example, when you can see clearly how far the gate has moved, but not for my ground signals, where they needed to move reliably back and forth through 90deg. (For gates I used a single pole switch, sprung to centre, so that the motor stopped when the switch was released).

The second diagram shows two additional switches and associated diodes (S3, D3 and S4, D4). These were micro-

The second diagram shows two additional switches and associated diodes (S3, D3 and S4, D4). These were micro-switches attached to the motor gearbox, and actuated by a lever (a long bolt) fixed to the motor spindle. With the signal in the middle of its travel, both S3 and S4 are closed, and current will flow through whichever one it can (ie the one with the diode in the same direction as switch S1). When the motor gets to one end of its travel, and opens one of the microswitches (S4 in the diagram) the motor will stop, because current cannot flow through diode D1, and the opposing diode D3. However, if the main switch S1 is reversed, then current can again flow (but with opposite polarity through D2 and D4) and the motor will run in reverse until switch S3 is opened by the movement of the motor. I have used a small resistor to step down the voltage to about 3-4V.

The photos show the micro-

The photos show the micro-switches attached to the motor, and the assembly with brackets added to fit it under the base-board. The motor shaft was connected to the signal using a short piece of flexible tube.

Brighton Road had control panels separate from the layout, so switch S1, is on the control panel, and only a single wire to the layout was required to operate each signal.

The final two photos shows a ground signal above and below the baseboard.

The final two photos shows a ground signal above and below the baseboard.

Ground signals for Brighton Road

From the modest amount of research I’ve done (mostly trawling through the Signalling Record Society books on LBSCR signalling) it appears the Brighton didn’t have a consistent approach to the use of ground signals. Some locations appear to have a minimalist approach, whilst in other places it seems that virtually every move is signalled. I opted for the latter for Brighton Road, and had ground signals either side of cross-

I’m not aware of any commercially available rotating actuators (apart from what was then the new and innovative approach of using radio control aircraft actuators) so I made my own, using ‘Clearbox’ motors as the basis. These are useful motors, running on 3-

I’m not aware of any commercially available rotating actuators (apart from what was then the new and innovative approach of using radio control aircraft actuators) so I made my own, using ‘Clearbox’ motors as the basis. These are useful motors, running on 3- I had a 15V AC supply on the layout, and I used this for motors which need to be run in both directions (turnouts, signals, gates). The basic principle of the electrics is shown in the diagram. Diodes were used to give half-

I had a 15V AC supply on the layout, and I used this for motors which need to be run in both directions (turnouts, signals, gates). The basic principle of the electrics is shown in the diagram. Diodes were used to give half-However, this didn’t provide an automatic stop when the signal rotated through 90deg. It worked ok for a gate for example, when you can see clearly how far the gate has moved, but not for my ground signals, where they needed to move reliably back and forth through 90deg. (For gates I used a single pole switch, sprung to centre, so that the motor stopped when the switch was released).

The second diagram shows two additional switches and associated diodes (S3, D3 and S4, D4). These were micro-

The second diagram shows two additional switches and associated diodes (S3, D3 and S4, D4). These were micro-

The photos show the micro-

The photos show the micro-Brighton Road had control panels separate from the layout, so switch S1, is on the control panel, and only a single wire to the layout was required to operate each signal.

The final two photos shows a ground signal above and below the baseboard.

The final two photos shows a ground signal above and below the baseboard.